SMAART Smart modular all-in-one robust laser machining tool

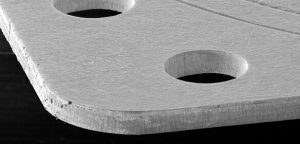

With the presentation of the SMAART project, the most important feature of the UKP lasers should be emphasized, namely the non-contact treatment with pulses that are so short that no significant heat conduction takes place. This opens up a large field of application for the production of micro components for various industries, such as medical, textile and watch industry, and the technology also has the potential to replace energy-intensive, ecologically questionable processes. Another major advantage of the USP technology is the high compatibility with a plant automation. The laser parameters required for the machining process can be checked from the NC control and synchronized with it.